Molten Metal Systems

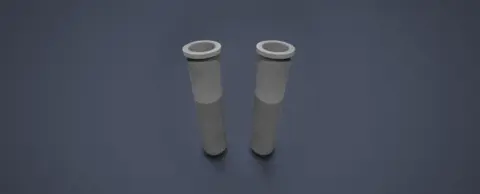

Gas Fired Heater Sheath

Morgan Advanced Materials' Molten Metal Systems business has developed a heater sheath and gas diverter system using advanced bonding technology for use in zinc melting and holding processes.

Our heater sheath is manufactured using a high pressure isostatic press to form the carbon bonded silicon carbide material into a consistent high quality product. The sheath is then further treated to give a very high resistance to oxidation and extended service life. The properties obtained provide zinc melters and galvanizers, using gas fired immersion heater furnaces, with a cost effective consumable which reduces maintenance and downtime.

Features

- Sheath in wear resistant silicon carbide for long life.

- High pressure isostatic press manufacture.

- Treated for additional anti-oxidation properties.

Advantages

- Superior erosion resistance.

- High resistance to chemical erosion.

- Excellent thermal shock resistance.

- High mechanical strength.

- High consistent density.

- Sheath and diverter from single source supplier.

- Long life for reduced cost.